How Automated Concrete Coordination Speeds Up the Metal Building Installation Timeline

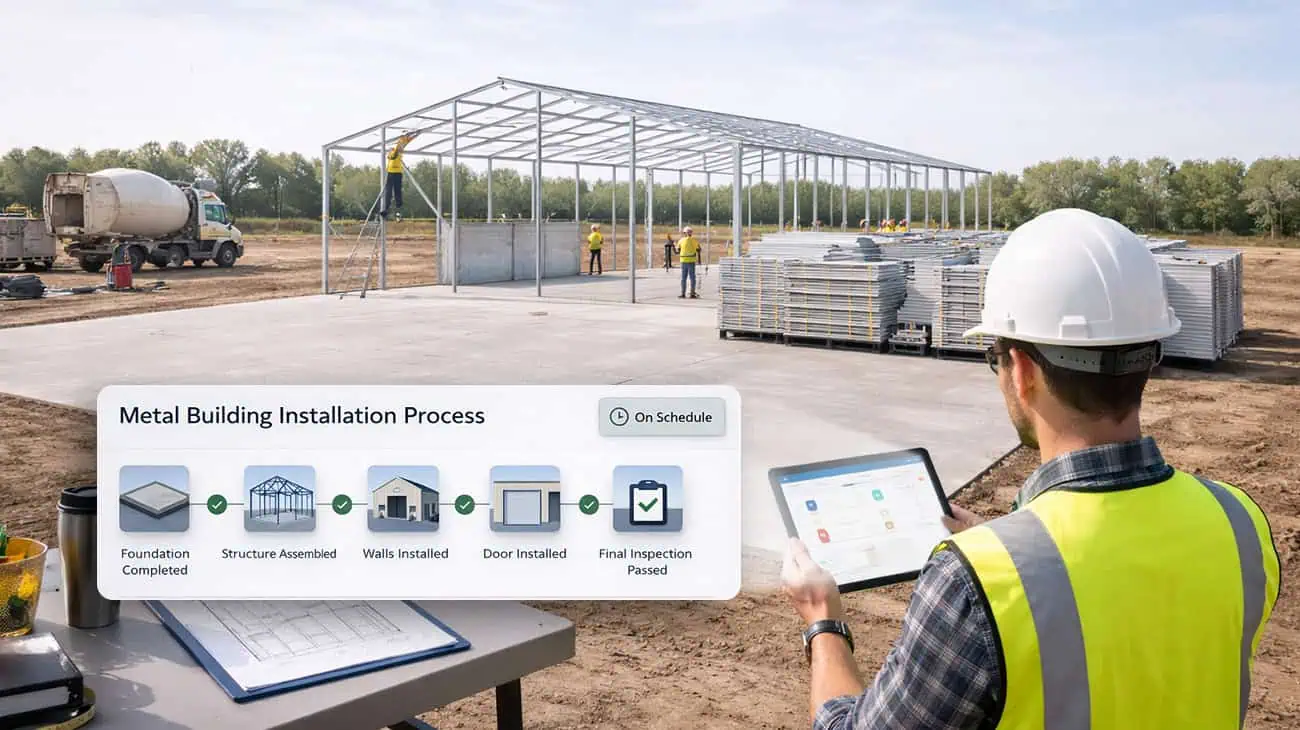

The metal building installation timeline doesn’t slow down because of manufacturing alone. It slows down when the concrete isn’t ready.

Customers searching for concrete contractors often experience delays, missed calls, and rescheduling. Meanwhile, the building waits.

Concrete coordination automation changes this.

When concrete coordination is automated at the system level, every qualifying order moves forward without manual intervention. Project details are shared early. Concrete scheduling begins sooner. Install readiness improves.

The result is fewer metal building install delays and more predictable timelines.

Automation doesn’t rush the process. It removes idle time.

For dealers, this means fewer frustrated customers. For manufacturers, it means better scheduling. For customers, it means buildings installed when expected.

Construction workflow automation works best when it starts before problems appear.

Explore our Categories

Get in touch with us

for more information…

If you need help or have a question, we’re here for you